REPP-Tile Carpet Tile

REPP-Tile Carpet Tile - is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Payment & Security

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Description

Description

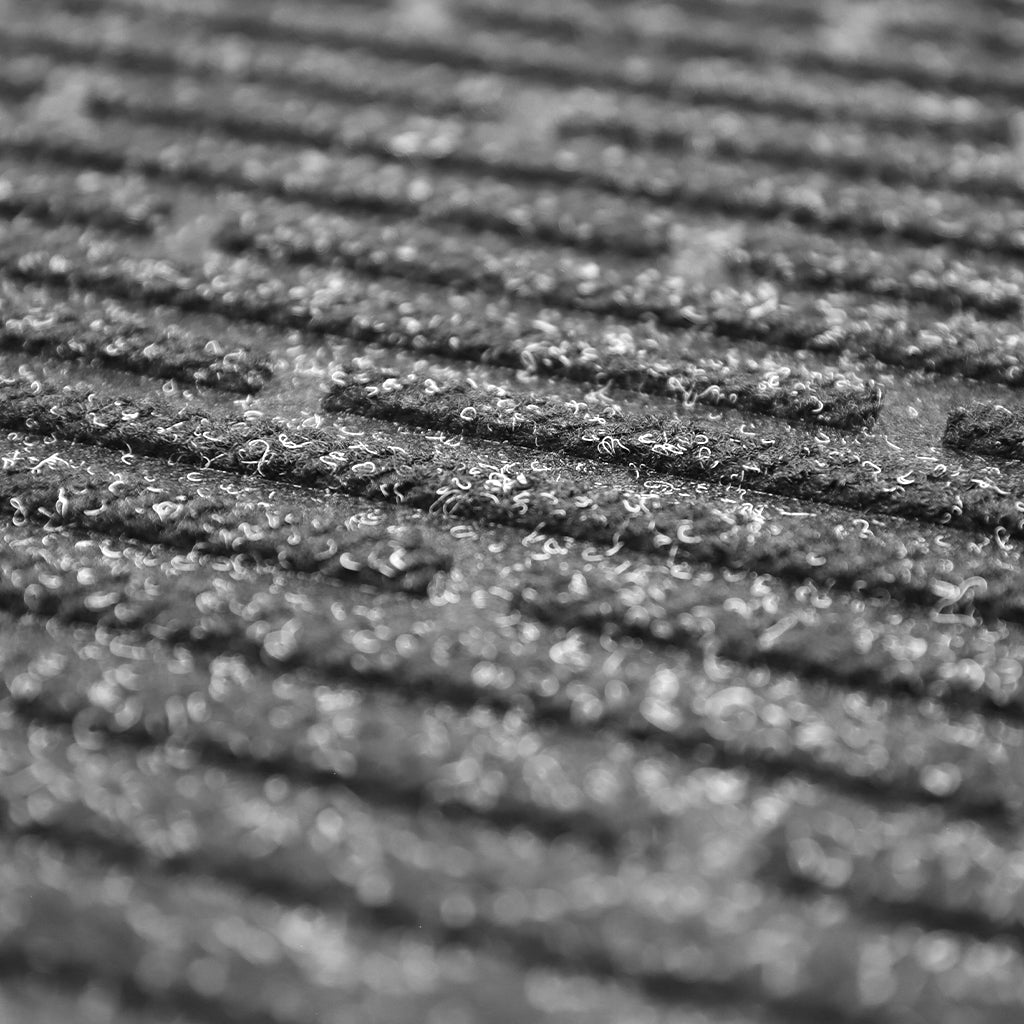

REPP-Tile is a high-performance entryway carpet tile made from 100% recycled PET, offering a sustainable flooring solution that can be recycled again and again. Designed for durability, these tiles resist staining and fading while maintaining a clean, professional appearance in high-traffic environments.

Each tile measures 19.5" x 19.5" and is available in an Anthracite Broken Diagonal pattern. REPP-Tile installs easily using TacFast tape (sold separately), and individual tiles can be replaced as needed to extend the life of the floor. Sold 16 tiles per case, REPP-Tile provides a safe, stable, and eco-friendly option for commercial entryways.

Recommended Uses

Recommended Uses

Material Specifications

Material Specifications

Available Sizes

Available Sizes

Care/Cleaning Instructions

Care/Cleaning Instructions

Installation Instructions

Installation Instructions

Fast Production

We know time is critical, and that's why we prioritize speed without compromising quality.

Standard production for most products is 5-business. Complex products may take a bit longer.