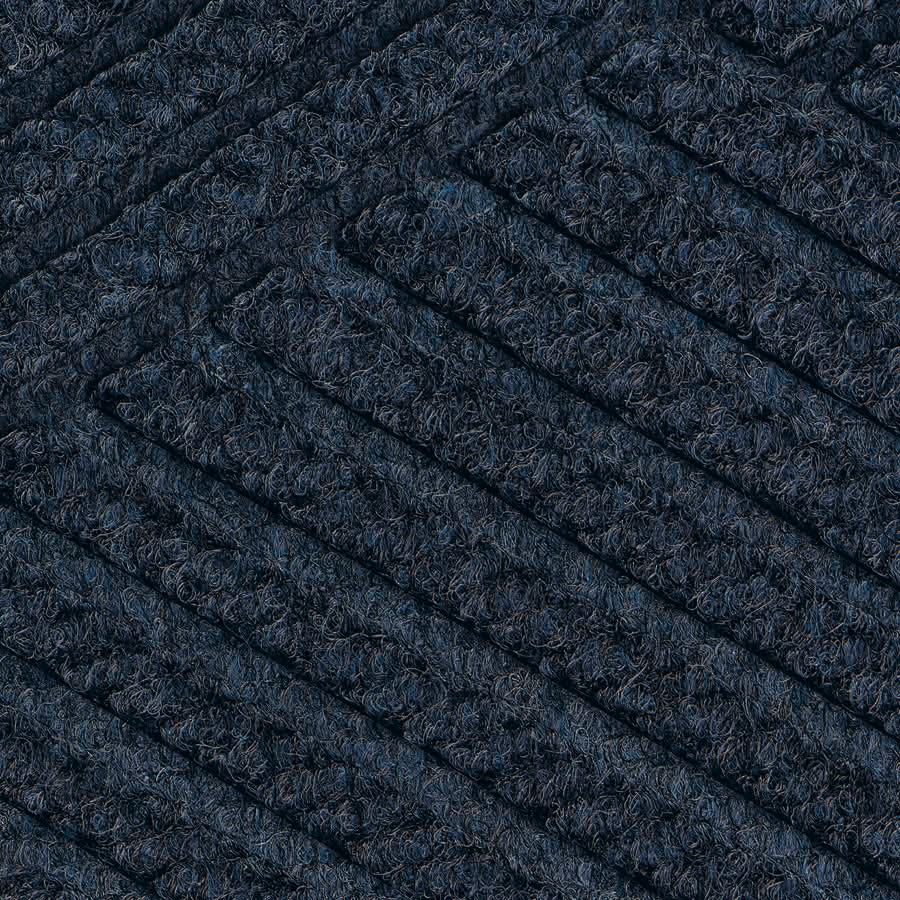

WaterHog Max Tiles

WaterHog Max Tiles - is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Payment & Security

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Description

Description

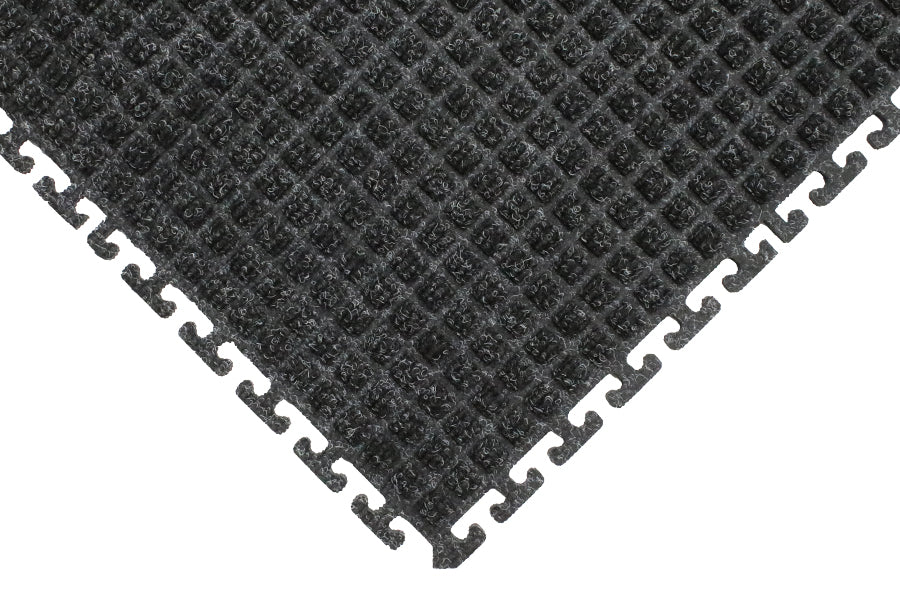

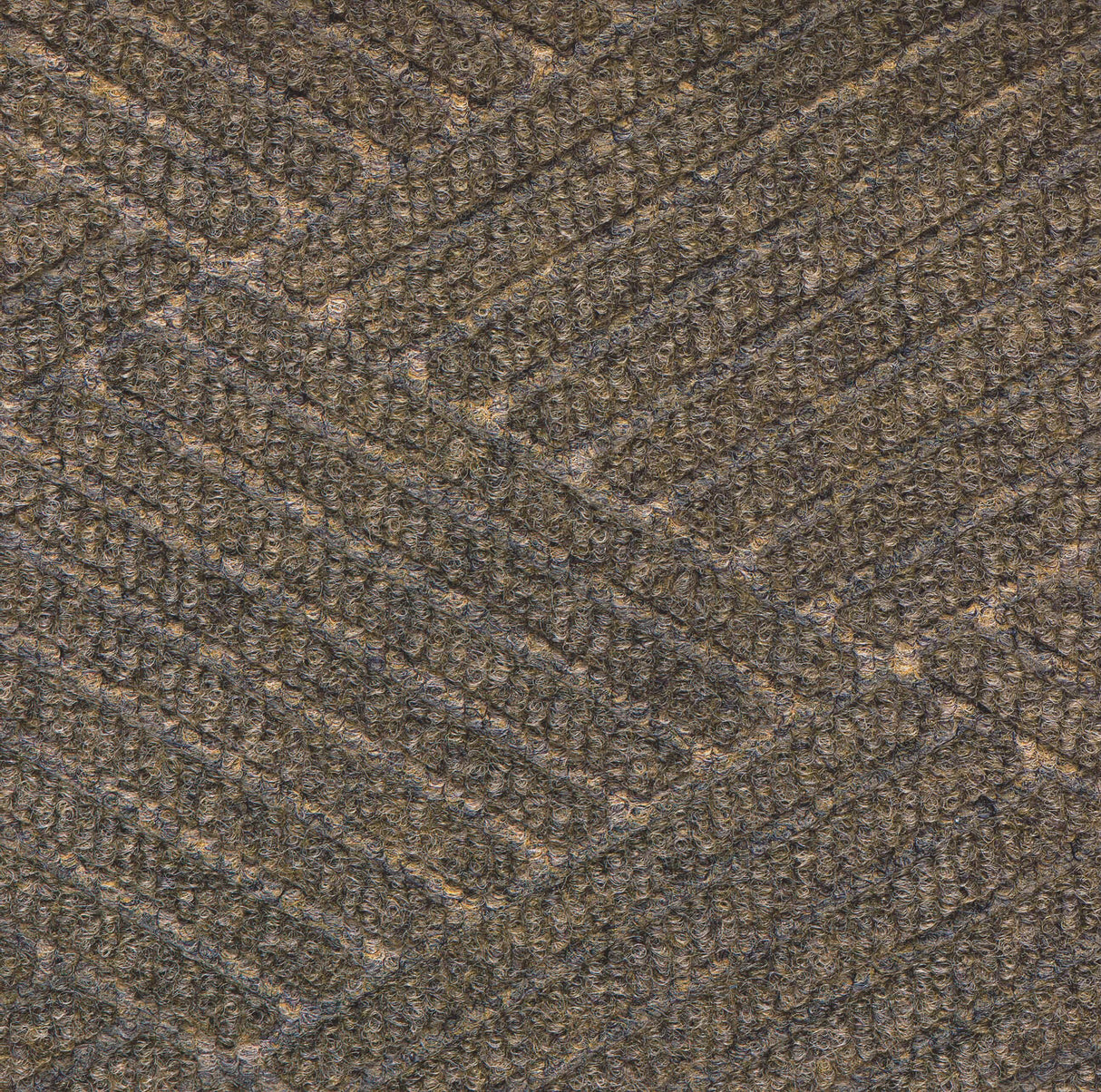

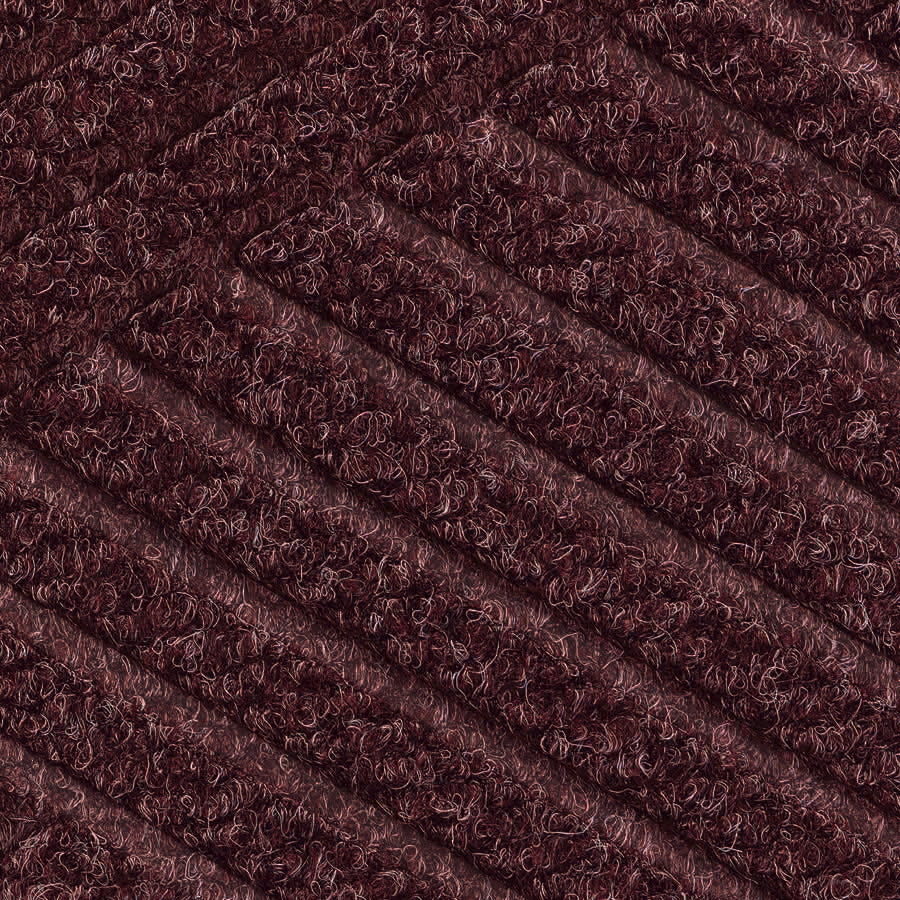

WaterHog Max Tiles are designed to create scalable flooring solutions for large interior or exterior entrance areas. The bi-level surface effectively scrapes dirt and moisture from shoes, trapping debris below shoe level to help reduce tracking and keep floors clean and dry.

Constructed with solution-dyed PET fabric made from at least 90% recycled content and reinforced rubber nubs to prevent crushing, these tiles deliver long-lasting performance and fade resistance. NFSI-certified for high traction, WaterHog Max Tiles feature a durable 100-mil SBR cleated rubber backing and can be installed as surface or recessed flooring. Individual tiles can be easily replaced as needed, with solvent-free adhesive required for installation and optional vinyl nosing available separately.

Roberts 6700 Multi-Purpose Solvent Free Adhesive is a suggested adhesive. 1 gallon covers approximately 115 sq.ft.

Material Specifications

Material Specifications

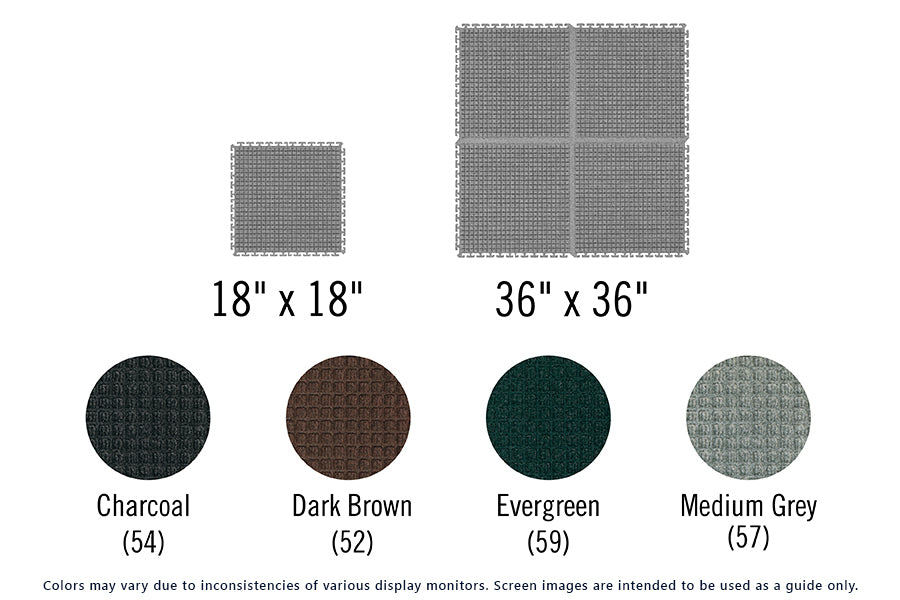

Available Sizes

Available Sizes

Care/Cleaning Instructions

Care/Cleaning Instructions

Installation Instructions

Installation Instructions

Fast Production

We know time is critical, and that's why we prioritize speed without compromising quality.

Standard production for most products is 5-business. Complex products may take a bit longer.